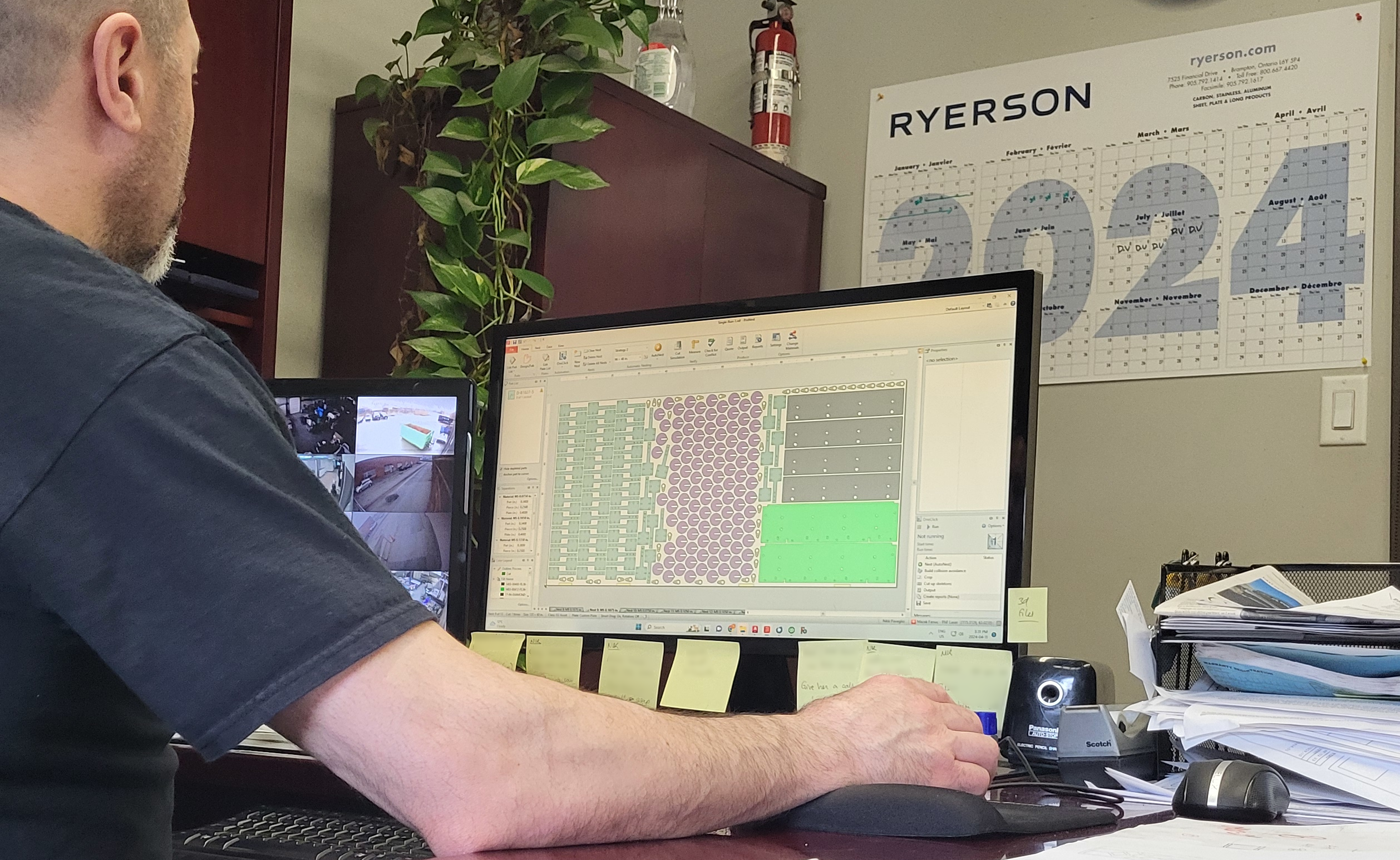

Programming

We layout our parts with advanced nesting software, optimizing material usage and costs. We accept all standard CAD file formats, or will create them for you to your specifications.

We layout our parts with advanced nesting software, optimizing material usage and costs. We accept all standard CAD file formats, or will create them for you to your specifications.

Utilizing fiber laser technology, we can cut sheets up to 78″ x 156″, handling material up to 3/4″ thick such as mild steel, stainless steel, aluminum, brass, copper, titanium, inconel, and high-strength alloys.

Executing with precision, we operate our 30 ton guillotine CNC shear which can handle materials up to 1/4″ thick and 10′ long.

Enhancing production efficiency with six CNC press brakes, capacities range from 40 to 150 tons, accommodating lengths up to 10′ for complex bending requirements.

Our facility is equipped to roll cylinders and cones up to 60″ in length and 1/4″ thick. For projects requiring brake rolling, we can accommodate lengths up to 10′ and thicknesses up to 3/16″.

Perform precise perforations or louvres on sheets up to 48″ x 144″, handling materials such as mild steel and stainless steel up to 1/4″ thick with our 50 ton CNC 20-station turret.

We create exceptional welds on materials up to 1/2″ mild steel, stainless steel, and aluminum. We guarantee quality bonds and assemblies tailored to your specifications.

Choose from a wide range of metal coatings and finishes to meet your requirements. We accommodate various surface treatments to enhance aesthetics and functionality.

PAF Metal Products is a well known and established custom metal fabrication shop in the Concord area. We have been in business since 1989 and we have been offering precision laser cutting since 1997.

At PAF, quality is not just a goal; it’s our commitment. We adhere to rigorous quality control procedures throughout every stage of production, ensuring the utmost precision in our parts and assemblies.

To maintain our quality standards, we implement additional measures such as GD&T principles, internal quality audits, daily analysis of parts, labeling systems, FIFO systems, adherence to IATF 16494 standards, and more.

We pride ourselves in making sure our customers are satisfied with the end product, combining decades of experience to help you create the finest custom metal fabrications in Ontario. We would be pleased to have an opportunity to provide you with a quote on your next project.